The main goal is to develop an accurate viscoelastic finite element procedure for designing dental restoration with better resistance to chipping, delamination and fracture along with improved aesthetics. For this purpose, we have already carried out a few studies that helps in understanding the behavior of Porcelain-veneered Yttria Tetragonal Zirconia Poly-crystal (Y-TZP) crowns.

Related Publications:

- Rupesh Shrestha, N. Reddy, S. Fredeen, Y. Zhang, and J. Kim, Functionally Graded Bi-material Interface for Porcelain Veneered Zirconia Dental Crowns: A Study Using Viscoelastic Finite Element Analysis, Dental Materials, Volume 40, Issue 8, Pages 1267-1281, 2024

- Abdulaziz M. Alshahrani, Chek Hai Lim, Jeongho Kim, Yu Zhang, “Transient Thermal Stresses Developed during Speed Sintering of 3 mol% Yttria-Stabilized Tetragonal Zirconia Polycrystals,” Dental Materials, 395(5), 522-528, 2023

- B. Sodergren, J. Wang, Y. Zhang, J. Kim, “Fracture Resistance of Ceramic-Polymer Hybrid Materials using Microscopic Finite Element Analysis and Experimental Validation,” Computer Methods in Biomechanics and Biomedical Engineering, DOI: 10.1080/10255842.2022.2038141, 02/11/2022.

- Camila S. Rodrigues, Sukirti Dhital, Jeongho Kim, Liliana Gressler May, Mark S. Wolff, Yu Zhang, “Residual stresses explaining clinical fractures of bilayer zirconia and lithium disilicate crowns: A VFEM study,” Dental Materials, 37:1655-1666, 2021

- S. Dhital, C. D. S. Rodrigues, Y. Zhang, and J. Kim, “Metal-ceramic and porcelain-veneered lithium disilicate crowns: a stress profile comparison using a viscoelastic finite element model,” Computer Methods in Biomechanics and Biomedical Engineering DOI: 10.1080/10255842.2021.1955869, 2021

- Manan, J. Kim, Campos, R. M. de Melo, Y. Zhang, “Design equation for mixed-mode fracture of dental interfaces using the Brazil-nut-sandwich test,” Journal of Engineering Materials and Technology, 143(4): 041006 https://doi.org/10.1115/1.4050972, 2021

- Dhital, C. D. S. Rodrigues, Y. Zhang, and J. Kim, “Viscoelastic Finite Element Evaluation of Transient and Residual Stresses in Dental Crowns: Design Parametric Study,” Journal of the Mechanical Behavior of Biomedical Materials, 103545, 2020.

- Dhital, A. Rokaya, M. R. Kaizer, Y. Zhang and J. Kim “Accurate and Efficient Thermal Stress Analyses of Functionally Graded Solids Using Incompatible Graded Finite Elements,” Composite Structures,222-110909, 2019.

- N. C. Ramos, M. R. Kaizer, T. M. B. Campos, Y. Zhang, J. Kim, Renata M. de Melo, “Silica-Based Infiltrations for Enhanced Zirconia-Resin Interface Toughness,” Journal of Dental Research, 98(4):423-429, 2019

- Kim, S. Dhital, P. Zhivago, Marina R. Kaizer, and Y. Zhang, “Viscoelastic Finite Element Analysis of Residual Stresses in Porcelain-Veneered Zirconia Dental Crowns,” Journal of the Mechanical Behavior of Biomedical Materials, 82:202-209, 2018

These crowns and fixed dental prostheses have seen quite a surge in their usage in past few years. The porcelain veneered over the zirconia crowns not only show better aesthetics but also improve the chemical durability and biocompatibility. However, these combinations are quite susceptible to chipping and delamination of the veneer layer. These deformations are caused by the residual and transient stresses present in the veneer layer during the cooling phase in the fabrication process. Direct measurement of these stresses are complicated owing to their complex geometry. Hence, numerical studies have been carried out since last four decades. Most of the previous studies has been on strips, monolithic discs or symmetrical crowns, employing a linear elastic framework. The porcelain used as veneering material, in all of these cases, shows viscoelastic behavior, which are not captured accurately by these linear elastic models.

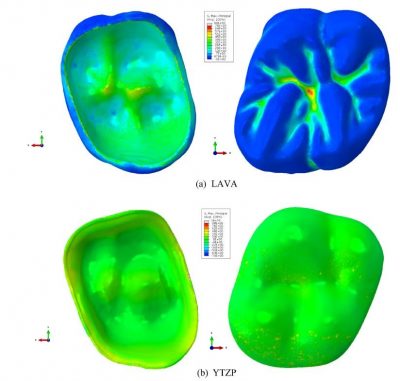

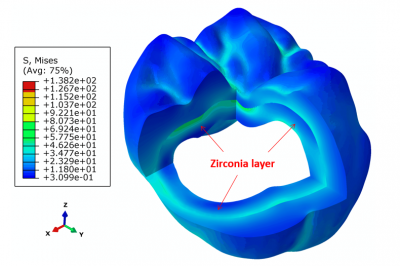

We, on the other hand, are carrying out the numerical study of symmetric as well as actual crowns, using ABAQUS, capturing the viscoelastic behavior of the veneering material. User-defined subroutine UEXPAN and UTRS help to better capture the viscoelastic behavior of porcelain throughout the entire firing cycle by defining shear relaxation dependent coefficient of thermal contraction, which is not available in ABAQUS. This not only helps us to capture the actual stress profile but also gives us an understanding for the causes of residual and transient stresses. More focus has been directed towards the temperature-dependent material properties, geometry, layer thickness, thermal contraction mismatch and cooling rate.

To put this into perspective, we have carried out thermo-mechanical analysis of porcelain (VM9 and Lava) veneered zirconia core. A temperature analysis was followed by mechanical analysis, taking the previous step temperature as loads. The obtained stress profile for VM9 veneered and Lava veneered crowns are shown below.

Fig 1: Contours of the maximum principal stress in the veneer (a) and core (b) layers in VM9/Y-TZP subject to controlled cooling.

Fig 2: Contours of the maximum principal stress in the veneer (a) and core (b) layers in LAVA/Y-TZP subject to controlled cooling.

Fig 3: 3D cut view of von Mises stress of the entire dental crown

This study showed us that smaller CTC mismatch between porcelain veneer and zirconia core as well as lower porcelain modulus can effectively reduce residual stresses in both veneer and core layers, as well as for both the cooling rates. Also, a slower cooling rate results in lower residual stresses in both those layers.

Loading...

Loading...

The pseudo-codes for the UEXPAN and UTRS subroutine used to capture the viscoelastic behavior of the veneer layer in our simulation is provided below:

Loading...

Loading...